ClassNK approves designs for LNG-fueled bulk carriers from K Line

Kawasaki Kisen Kaisha, Ltd. (“K” LINE) jointly developed two conceptual designs for LNG-fueled and battery-powered energy-saving bulk carriers and obtained Approvals in Principle (AIP) from Japan’s ship classification society Nippon Kaiji Kyokai (ClassNK).

“K” LINE developed a conceptual design for a 200,000-ton class Capesize bulk carrier in collaboration with Namura Shipbuilding Co., Ltd., and Taiyo Electric Co., Ltd.

The other design was jointly created by “K” LINE, Shin Kurushima Sanoyas Shipbuilding Co., Ltd., and Taiyo Electric Co., Ltd for a 90,000-ton class post-Panamax bulk carrier.

By selecting low-carbon LNG as the primary fuel source, an energy-saving vessel has been designed that helps reduce greenhouse gas emissions.

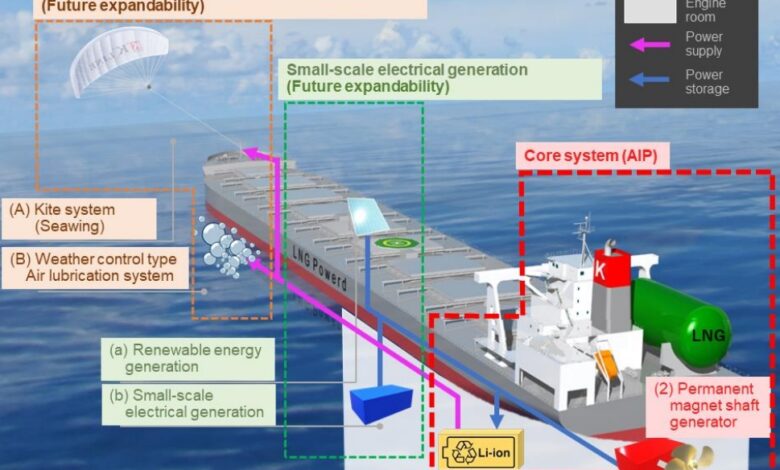

The design was further enhanced by adopting permanent magnet (PM) shaft generator (Note 2) technology, along with lithium-ion batteries, which are already being used in a wide range of fields in society.

Moreover, by utilizing batteries as part of the platform for power supply onboard, the aim is to further reduce emissions going forward by later adding green energy sources with energy-saving technology.

AIP technical features and their benefits

1. Utilizing LNG fuel

- Reduction of greenhouse gas emissions by 25% to 30% compared to the use of conventional heavy fuel oil.

2. Adoption of shaft generator technology

- By producing electricity with shaft generator technology, fuel efficiency is improved compared to power generation with a conventional dual fuel generator. (By using shaft generator and battery technologies, an emissions reduction of about 2.5% to 3.0% is expected, compared to an LNG-powered vessel without those two technologies.)

- By eliminating the need to operate generators during voyages, the maintenance workload for the ship’s crew will be significantly reduced along with the associated maintenance costs.

- By adopting PM shaft generators, efficiency is improved by about 10% compared to conventional shaft generators

3. Battery technology adoption

- Small-capacity batteries (reducing emissions during voyages) Small-capacity batteries with excellent charge and discharge rates will be used for auxiliary power during peak hours of onboard demand. They will also be utilized to store surplus electricity.

- Large-capacity batteries (reducing emissions during cargo handling) In the new post-Panamax carrier design, emissions will be reduced by using large-capacity batteries instead of a dual fuel generator during cargo loading and unloading.

- (The number of dual-fuel generators installed can be reduced by one.) In the new Capesize carrier design, the battery capacity will be greater due to the amount of power required during cargo handling. Here emissions during cargo handling will also be reduced by enabling vessel connection to shore power.

In addition to the equipment for greenhouse gas emissions reduction under the recent AIPs, the aim is to further reduce emissions going forward by installing various optional technologies.