Sanmar Shipyards and IGUS have joined their expertise to build “Shore Electric Bunkering System

Sanmar Shipyards makes five deliveries in a week

Sanmar Shipyards has joined forces with IGUS, the world’s largest energy chain systems manufacturer, to develop and build a new compact ‘electric bunkering’ system that can supply various vessel types with onshore power.

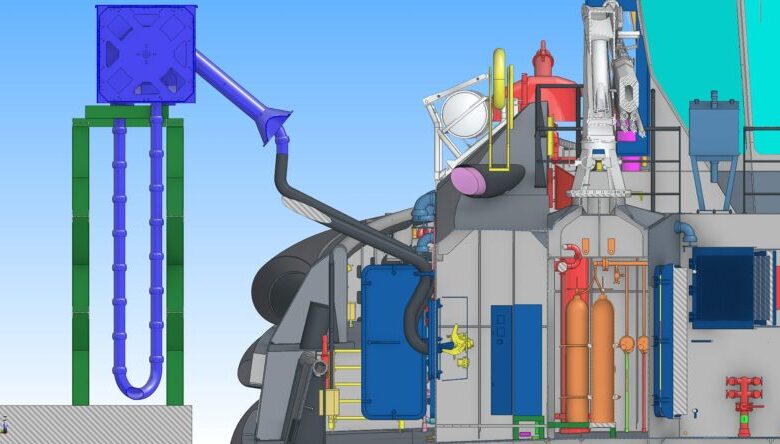

By joining forces and expertise, the two companies have designed and built a simple to operate compact quayside Shore Power Dispenser System, which can be operated by just one crew member.

The modular design allows an extension of the dispenser system to provide higher charging power capacities easily. Each cable dispenser module can handle 500A current capacity (up to 1000V AC).

For Sanmar, as a Turkish shipyard and tugboat operator, the cooperation with Igus enables it to offer a charging infrastructure for the ports and is part of its mission to lead the tug and workboat industry’s efforts towards an environmentally friendly, sustainable, low- and zero-emission future.

Sanmar is already working in collaboration with Canadian naval architects Robert Allan Ltd and battery energy storage provider Corvus Energy to build and develop the ground-breaking ElectRA range of electric tugboats – five vessels ranging from 19m to 28m in length and up to 70 tonnes of bollard pull.

Tamer Geckin, R&D and Electrical Systems Director of Sanmar Shipyards, said: “We are delighted to have been able to share our expertise, skills and knowledge with Igus.

Our vision of a future sustainable carbon-neutral tug and towing sector will depend on simple, easy-to-use and efficient infrastructure at ports and harbours around the world.

We are proud to be at the heart of this transformation through innovation and technological advance.”

Martin Tilling, Shore Power Systems Industry Manager of Igus GmbH, said “As “Igus” we are aware that more and more ports are confronted with an increased public awareness of environmental issues. Stricter guidelines are forcing ports to implement more environmentally friendly technologies.

Our customised energy supply systems for providing vessels and tugboats at berth with shore power are the solution to reduce air pollution, noise and vibration.

As a part of our global company vision such as “Improve all types of motion with motion plastics, with CO2 neutral footprint and zero plastic wate”, we are delighted to collaborate with Sanmar for their new design green tugboats.

From the start of their collaboration, both Igus and Sanmar understood that it was important to keep their system simple and modular so that the system can be adapted to the charging capabilities of each individual port.

The cable management system, combines standard components and is operated with a radio remote control so there is no need for additional personnel shore side to operate it. Connection and disconnection require only a few minutes.

The two project partners are also sharing their experiences for the automated connection system which will be required if there is only a short period available for charging.

In short, the new Sanmar and Igus ‘electric bunkering’ system is:

- A modular and compact shore power dispenser system,

- Each cable dispenser module can provide 500A current capacity (up to 1000V AC) and can be extended for higher charging capacity by increasing the quantity of modules

- The cable dispenser module is installed on support structure that height is designed according to port requirements

- Selective deployment length and adjustable arm length

- A ready-to-install plug-and-play solution

- Extra cable protection by Triflex TR energy chain

- Uses standard components instead of project-specific special solutions

On the other hand Sanmar Shipyards recently delivered five vessels in a single week from its extensive catalogue of technologically-advanced and environmentally-aware tugs and workboats to operators in Europe and the Americas, including two new first-time customers in Bulgaria.

The diverse range of four tugs and a mooring boat all constructed at Sanmar’s purpose-built state-of-the-art shipyards in Türkiye have been delivered to SAAM Towage in Panama, MedTug in Rotterdam, Sanmar’s own fleet and Bulgarian operators BMF Tug Service and Trans-Port-Lane.

Ruchan Civgin, Commercial Director of Sanmar Shipyards, said: “The first half of the year has been good for us and we are in a strong position going forward.

These latest deliveries demonstrate how we can offer a wide range of tugs and workboats based on innovative designs and using the latest technologies, to meet the different needs of our clients.

Our shipyards operate to the highest environmental standards and we are at the forefront of the drive to a sustainable low-emission and emission-free towage industry, and I am pleased that these latest deliveries confirm once again that we are able to serve the varying needs of both huge international operators and those providing towage and mooring services on a much smaller scale.”

Bogacay XLIII, renamed SAAM QUIBIAN by her new owners is the seventh Sanmar tug delivered to SAAM Towage. 70-tonnes ahead bollard pull (BP) tug is based on the exclusive-to-Sanmar RAmparts 2400SX design from renowned Canada-based naval architects Robert Allan Ltd. It will work in Panama Canal Waters alongside one of its six sister tugs previously delivered to SAAM Towage by Sanmar.

At the same time, Sanmar also delivered the tug SANMAR TERMINAL XXV, a RAstar 2800 design from Robert Allan Ltd, which had been part of its own fleet in Türkiye, to MedTug SA. She has been renamed MED BELLATRIX and will work in the Port of Rotterdam.

She can achieve 75-plus tonnes bollard pull ahead and is the fifth tugboat in total that Sanmar has delivered to MedTug SA.

Meanwhile, the new-build DELICAY X has joined Sanmar’s own fleet operations at Izmit, Türkiye. The ATD tug, which can achieve a BP of 75 tonnes over the stern, is based on the exclusive-to-Sanmar TRAktor-Z 2500SX design from Robert Allan Ltd.

Sanmar also delivered its specialist compact tug GOKCAY II to new client BMF Bulgaria where, renamed AQUILA 2, it will work in Burgas, the largest port in Bulgaria. The vessel, which can achieve a BP of 16 tonnes, had been in stock at Sanmar’s Altinova shipyard.

Based on the, again exclusive-to-Sanmar, RApport 1600SX Mooring Boat design from Robert Allan Ltd, the Gokcay Class has been designed to address the challenges of modern, line-handling and smaller ship-handling tugs.

In its other sale to a new customer, Sanmar delivered VECTOR, an 11m mooring boat from its fleet in Türkiye, to Trans-Port-Lane Bulgaria where it will work in Varna on the Black Sea.